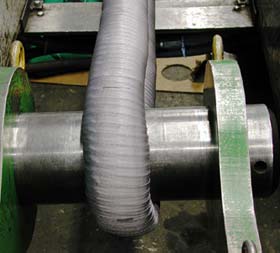

Eye Wrap of a 175,000 lbs Capacity Twin-Path® Extra Sling

|

There is the occasional application where a Twin-Path® Extra sling must fit into narrow hardware or narrow hoisting collars. For the occasional lift we have developed a system which allows us to wrap a portion of the Twin-Path® Extra sling to about 60% of its normal width. The wrapping is done with seat belt webbing which not only compresses the sling body, but at the same times provides some sort of sling protection. The wrapping process is done without ANY glue or other ‘stuff’. After the lift the wrapping can be taken off the sling without any residue sticking to the sling itself. The wrapping, if not severely damaged, can be re-used. Wrapping must be done at the Unirope facility because unique equipment is needed, plus we have to proof load the sling after the wrapping process. Note: The wrapping process can ONLY be done with Twin-Path® Extra slings. |

||||||||

|

||||||||

| Note the stiffness of the wrap which makes it easier to rigg. Picture was taken after the proof load to double the sling capacity. |

||||||||

|

||||||||