TWIN-PATH® and Roundsling Inspection

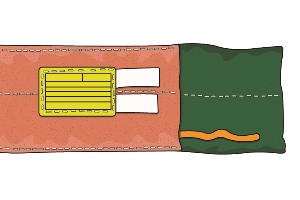

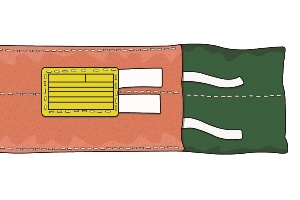

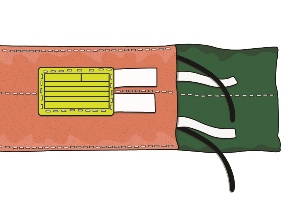

- Check-Fast® External Warning Indicators (EWI) and legacy Tell-Tails, if installed in the type of sling, should extend 1/2” past the tag area of each sling. If the Check-Fast® (EWI) or both Tell-Tails are not visible remove the sling from service. If the EWI or Tell-Tails show evidence of chemical degradation, remove the sling from service and send to Unirope for repair evaluation.

- If Fiber Optic Inspection is installed in the sling, inspect by allowing light to enter the fiber optic cable. If the fiber optic cable does not transmit light from end to end, remove the sling from service and contact the manufacturer for repair evaluation.

- Slings should be inspected for evidence of cutting or tearing of the outer cover. Slings with cuts should be removed from service and sent back to the manufacturer for repair evaluation. Damage to the cover may indicate core damage.

- Inspect slings for evidence of heat damage. Slings with polyester or Covermax covers should not be exposed to temperature above 82°C/180°F. Aramid Sparkeater Slings should not be exposed to temperatures over 149°C/300°F. K-Spec™ Core Slings should not be exposed to temperatures above 82°C/180°F. Cold temperature exposure down to minus 40°C/minus 40°F do not effect the strength of the products. Other temperatures should be referred to the manufacturer.

- Slings using aluminum fittings shall not be used where fumes, vapors, sprays, or mists of alkalis or acids are present.

- If any part of the sling shows evidence of chemical degradation or damage, remove the sling from service. Return the sling to Unirope for repair evaluation.

- Twin-Path® and Uni-Path® Lifting Slings and any fittings attached should be the subject of frequent and regular inspections. In addition to the initial inspection by a competent person and frequent written inspections, the slings should be visually inspected before each use.

- Written inspections should be performed as required and documents of such inspection by a competent person shall be kept on file in the safety department of the plant or site where used. Inspections may be done more often based on frequency of use, severity of conditions, experience of past service life.

- Slings should be examined throughout their length of abrasion, cuts, heat damage, fitting distortion or damage, tag legibility, and if any doubts are held by the inspector, the sling should be removed from service. Core integrity is determined by fiber optic light transfer if this type of tell-tail is installed in the sling. If a deterioration is found, the sling must be removed from service and returned to Unirope® for evaluation.

- Slings removed from service that are not capable of repair should be destroyed and rendered completely unfit for future use.

- Abrasion, heat damage or cuts to the cover may indicate a loss of strength to the load core and these slings should not be used until evaluated by the Unirope®. At area of damage, Unirope® will open the cover and have the core yarns counted and visually inspected.

Uni-Path® and all other roundslings are constructed from a single load carrying yarn bundle. ANY damage to this bundle may result in sling failure. |

Twin-Path® slings are constructed from 2 or more INDIVIDUAL load bundles and are actually two or more separate slings in one. This is unique backup protection. |

If the outer cover is damaged the sling should be taken out of service. Shown above is a double cover with contrasting colours. Some Roundslings have a single cover ONLY. |

The patented Check-Fast™ Early Warning Indicator (EWI) system (yellow/red), installed in one path. If the sling is mistakenly overloaded the EWI is designed to disappear before the sling fails. The EWI is combined with our optional Fiber Optic (FO) System. |

Traditional Shrink Tails disappear when the sling has been over stretched. In 2010 this style has been replaced with the Check-Fast™ EWI System (see picture on left). Older slings with Tell- Tails will still be serviced, inspected, repaired and re-certified. |

Up until 2010 the combination of Fiber Optic Tell Tails and traditional Shrink Tails was standard on all Twin-Path® slings with K-SPEC™ yarns. This style has been replaced with the Check-Fast™ EWI System. The fiber optic cable runs through the entire sling length. If no light travels through the cable then there is the potential of core yarn damage. |

Below:

Lifting of a 220 ton rotor with Twin-Path®