Inspection of Chain Mesh Slings

Unirope Chain Mesh Sling Inspection Criteria (based on ASME B30.9-1)

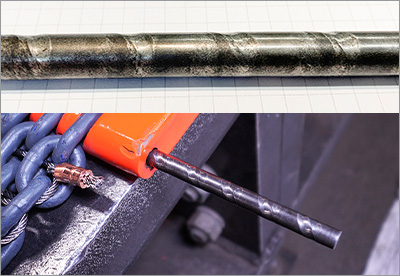

Worn or abraided chain links. Gouged and nicked chain links. Stretched links due to overloading the sling |

Replace scorred and indented CMSS shaft rods Replace for broken tie-cables, distorted mesh structure |

| Use of Grade 100 Alloy Chain Mesh Slings in hot environments | |||

|---|---|---|---|

| Temperature of Chain in degree | Temporary Reduction of Rated Load while at Temperature | Permanent Reduction of Rated Load after Exposure to Temperature | |

| Celsius °C | Fahrenheit °F | ||

| Below 204 | Below 400 | None | None |

| 204 | 400 | 15% | None |

| 260 | 500 | 25% | 5% |

| 316 | 600 | 30% | 15% |

| 371 | 700 | 40% | 20% |

| 427 | 800 | 50% | 25% |

| 482 | 900 | 60% | 30% |

| 538 | 1000 | 70% | 35% |

| Over 538 | Over 1000 | Remove from Service | Remove from Service |

Chain slings shall be removed from service if any of the following conditions are present:

- missing or illegible sling identification.

- cracks or breaks.

- excessive wear, nicks, or gouges.

- stretched chain links or fittings.

- bent, twisted, or deformed chain links or fitting.

- evidence of heat damage.

- excessive pitting or corrosion.

- lack of ability of chain or fittings to hinge freely.

- weld slatter.

- other conditions, including visible damage, that cause doubly as to the continued use of the sling.

- broken or damaged connection steel cables.

- any damage to the shaft rods in SLIM CMSS fittings.

- a 15% reduction of the original cross-sectional area of any point around the hook opening of the end fitting.

- visible distortion of either end fitting out of its plane.

For sling inspection, re-certification and proof testing call Unirope®