Polydyne™

Polydyne is a double-braided rope that utilizes a polyester sleeve over a nylon core. Despite the dissimilar stretch characteristics of these fibers, Yale engineers have produced constructions where both fibers contribute.

The resulting rope has high breaking strength and more stretch in its working load range, which in many applications is a plus. Polydyne is up to taking more dynamic abuse without being degraded prematurely. Take special note of the working energy-absorption rating, which is the amount of energy a rope absorbs before reaching its working load. The ultimate energy absorption of this rope is also correspondingly high. All this and a tough polyester jacket make this a long-wearing rope with extraordinary dynamic capabilities.

Crystalyne™

Crystalyne is a double-braided rope constructed with an inner load-bearing core of Vectran Liquid Crystal Polymer (LCP) and has a tough polyester outer sleeve. LCP is more tolerant of bending than other high-modulus fibers and is not as affected by overloading.

Crystalyne exhibits more tension cycles to higher percentages of break than all our other high-modulus offerings. Unlike ultra-high-molecular-weight polyethylene (UHMPE) ropes, LCP fiber has little or no tendency to creep and can be used to hold tight tolerances in rope assemblies.

Vectran is hydrophobic, meaning it cannot absorb water. This rope is spliced using the same technique as our Maxibraid Plus, resulting in a termination that finishes shorter than conventional splice techniques and remains supple.

Stainless Steel Wire Rope and Cable

| Type 302/304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine- and salt water. | Type 316 stainless steel is the standard high corrosion resistant steel for rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing and textile industries. It has the best pitting resistance in marine and salt water and can be used in temperatures up to 480°C (900°F). |

Galvanized Cable (Carbon Steel)

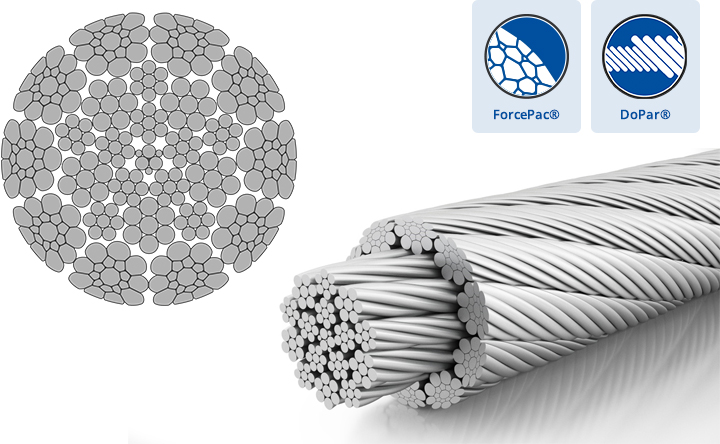

Python® Compac® 35

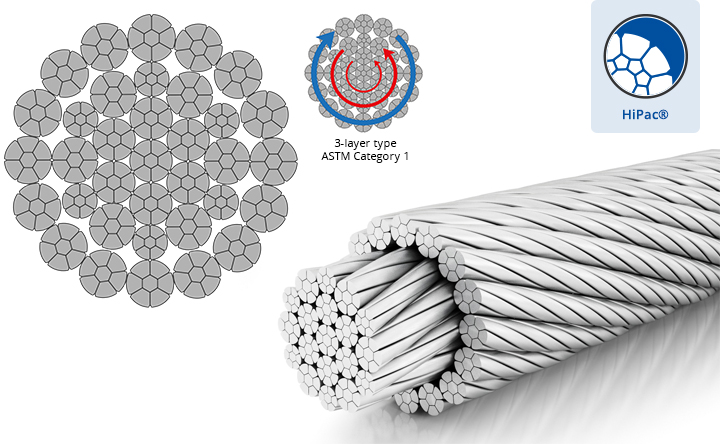

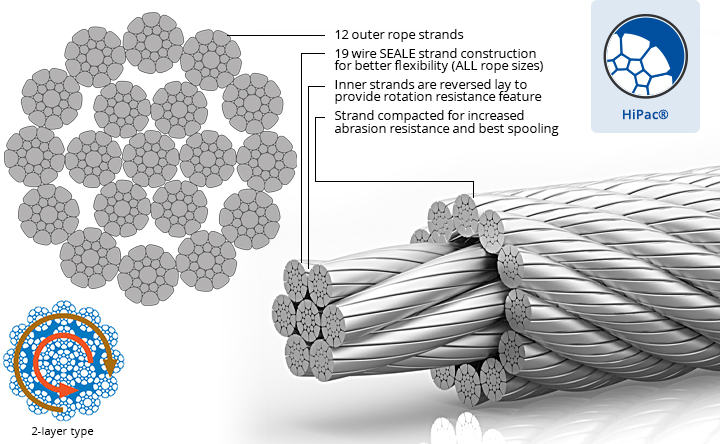

Non-Rotating Wire Rope (HiPac®)

Python® Compac 18

Rotation resistant for multi-layer drums (HiPac® strand compacted)

Class 19×7; Rotation Resistant Wire Rope

8×19 / 8×36; Spin Resistant

Python® Ultra

Super high strength for engineered applications (Force Pac® swage compacted)