Mega Max

Rope Characteristics

Mega Max is double braid rope with a unique design that provides the ultimate in abrasion protection while still providing the highest strength possible, all in a Ultra High Molecular Weight Polyethylene (UHMWPE) fiber construction.

The load bearing core is made of 12-strand Ultrex and provides 100% of the strength in this design. It is then over-braided and protected again by UHMWPE fiber, the most abrasion resistant fiber available.

Breaking Strengths

| Finished Diameter (Inches) |

Core Diameter (Inches) |

Weight (Lbs/100f) |

Average Spliced Break Strength* (Lbs) |

Minimum Spliced Break Strength* (Lbs) |

Maximum Working Load 5:1** (Lbs) |

|---|---|---|---|---|---|

| 5/8 | 1/2 | 9.7 | 39,250 | 35,325 | 7,850 |

| 3/4 | 9/16 | 11.9 | 47,000 | 42,300 | 9,400 |

| 7/8 | 5/8 | 17 | 55,500 | 49,950 | 11,100 |

| 1 | 3/4 | 21.6 | 75,000 | 67,500 | 15,000 |

| 1-1/8 | 7/8 | 26.6 | 98,000 | 88,200 | 19,600 |

| 1-5/16 | 1 | 35.5 | 120,000 | 108,000 | 24,000 |

| 1-1/2 | 1-1/4 | 55.4 | 172,000 | 154,800 | 34,400 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

|||||

| Finished Diameter (mm) |

Core Diameter (mm) |

Weight (Kg/100m) |

Average Spliced Break Strength* (kg) |

Minimum Spliced Break Strength* (kg) |

Maximum Working Load 5:1** (kg) |

|---|---|---|---|---|---|

| 14.4 | 17,815 | 16,034 | 3,563 | ||

| 17.7 | 21,335 | 19,202 | 4,267 | ||

| 25.3 | 25,195 | 22,676 | 5,039 | ||

| 32.2 | 34,050 | 30,645 | 6,810 | ||

| 29 | 22 | 39.6 | 44,490 | 40,041 | 8,898 |

| 33 | 25 | 52.9 | 54,480 | 49,032 | 10,896 |

| 38 | 32 | 82.5 | 78,085 | 70,277 | 15,617 |

| * Knots and abrupt bends significantly reduce the strength of all ropes and lower maximum working load. ** Working load is based on static or moderately dyanmic lifting/pulling operations. Instantaneous changes in load, up or down, in excess or 10% of the rope’s related working load constitute hazardous shock load and would void the normal working-load recommendation. Consult Yale Cordage for guidelines for working loads and the safe use of rope. |

|||||

Rope Details

Rope Benefits

|

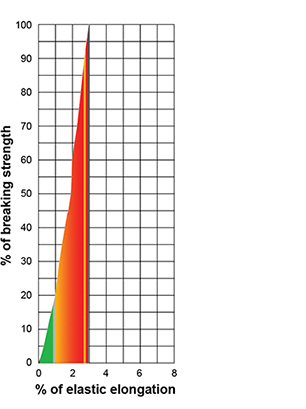

Elastic ElongationThe coloured area under the curve represents the rope’s energy absorption capability.

|