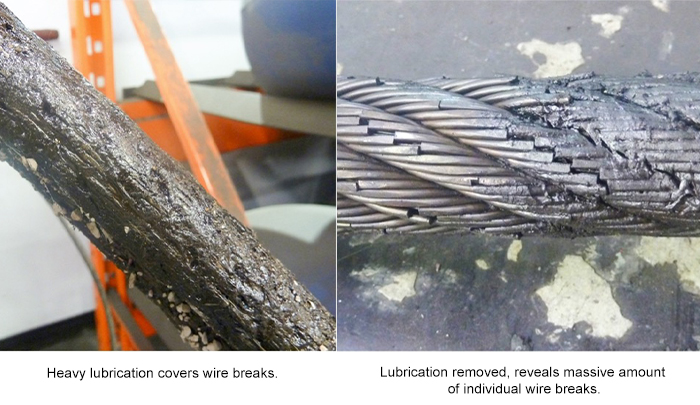

Too Much Lubrication Prevents Rope Inspection

During manufacturing, wire rope is lubricated to reduce internal and external frictions. Tests performed by the University of Stuttgart, Germany, have shown that non-lubricated ropes will only last 1/3 of well lubricated ones. It is important to select the correct lubrication because thick and heavy lubes will just cover the outside of the rope without penetrating to the inside. In fact, thick lube will be locking-in moisture, accelerating internal corrosion. The result will be that visual rope inspections may not detect outside and inner (valley) breaks because thick lubricant will hide them. If you have to inspect thick-lubed wire rope you must remove the lube in regular intervals to perform proper inspections.