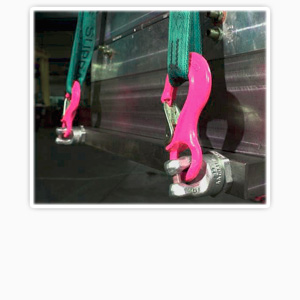

DescriptionThe first generation of lifting points with a universal connection for all slinging means (hook and ring assemblies, endless slings, round slings, loops, etc.). With a double ball bearing for jerk-free turning, swiveling and tilting. Even under full load, can be turned in a 90° position from the bolt centre line. Not suitable for permanent swiveling under full load. The optimized design prevents the lifting points as well as the load from being damaged. Maximum WLL with the smallest thread diameter. Thread length: 36 mm. Version PP-S: the standard universal connection with eye hooks for ring assemblies, round slings, wire ropes, and hook assemblies. Choose the attachment points in such a way that the introduced forces are accommodated by the work piece without being deformed. Work piece material, at least 1.0037 (St 37). For light metals, non-ferrous heavy metals, and grey cast iron, the thread type allocation must be done in such a way that the WLL of the thread type fulfills the requirements of the respective work piece. Make sure the bolting surface is plain. Ensure an appropriate bore depth to facilitate an optimal sitting of the engaging surface. For a single transportation procedure, bolting in and fastening tightly with a flat wrench is enough. Without a washer, the seat-engaging surface of the Power point (D) must completely lie onto the surface of the work piece. Is the Power point to be permanently loaded, it must be tightened with a torque of 150 nm. When impact loaded or operated in environments with skewing and vibrations, unintentional loosening can happen, especially if through bolts with nuts are used. Securing possibilities: use of a liquid thread securing medium, e.g. Loctite (follow the manufacturer's recommendations), or positive bolt securing, for example, using a castellated nut with a split pin, a counter nut, etc. |

|

|

|

|